This equipment can be used to take representative samples.

Samples of agglomerates, aggregates, powders, granules or liquids in gravity flow.

Various models are available, to suit flow cross-sections from DN 20 to DN 500.

A trough, moving in a circular motion at a constant speed of 0.6 m/s, passes under the product flow to collect a sample uniformly over the entire cross-section.

The cross-section of the trough is radial, and its angle can vary depending on the size of the product to be picked, the flow rate and the quantity required for each pass.

A control panel is used to run a sampling cycle (which may include one or more passes under the flow). The equipment can be used to programme and count samples at regular or variable intervals.

This equipment enables representative samples to be taken.

All parts in contact with the products are made of 304 L stainless steel (316 L on request).

The drive is provided by a geared motor, 220 V single-phase or three-phase, 380 V three-phase.

The complex can be adapted to meet specific operating conditions.

A mobile trough moves at a set speed under the full width of the product throw and evacuates the captured sample:

A control panel is used to run a sampling cycle (which may include one or more passes under the flow). The equipment can be used to programme and count samples at regular or variable intervals.

This equipment enables representative samples to be taken.

All components are made from materials suitable for the product to be sampled, such as steel or stainless steel. The design is particularly robust. System dimensions and configuration depend on plant layout

Removal of chips, pellets or other materials during the emptying of the moving floor lorry.

Sampler adaptable to a gravity chute for powder or granules

Staff safety during the operation.

A mobile trough of a size adapted to the desired quantity is fixed to the end of a rotating arm. The sample is taken at the end of a conveyor belt. The trough is positioned under the product flow and then emptied into a recovery tank for the accumulated samples. Equipment can be adapted to suit conditions of use

An electrical control box equipped with a touch-sensitive display and a PLC enables :

All components are made from materials suited to the product and operating conditions (generally painted steel).

Powder and granule sampling on gravity flow circuits.

A mobile trough with a specific opening, driven by a sectorial radiating movement, travels at a specific speed.

Each time it passes, it collects and discharges an « elementary » sample.

Each sample is proportional:

An electrical control box equipped with a touch-sensitive display and a PLC enables :

All components are made of materials suited to the product and operating conditions (usually stainless steel), and are particularly robust.

Powders, granules, agglomerates… At rest, the sampling system has no influence on product flow. There is a seal between the sampler and the enclosure.

A spoon piston is inserted under the product flow for the time required for loading. When the scoop is full, the piston returns to its position above the sample hopper. The piston then rotates through 180° to drain the product. If necessary, a metered gas injection facilitates evacuation. Rotation movements are transmitted by pneumatic cylinders.

An electro-pneumatic or pneumatic control box is used to set the muscular or automatic (programmed) sampling cycle, and provides the safety features required for operating conditions.

Sealing systems ensure that the spoon piston is sealed and scraped. All parts in contact with the product are made of stainless steel, plastic or PTFE. Standard cylinder (light alloy), seals (Nitrile, Viton, PTFE). The whole unit is encased in stainless steel

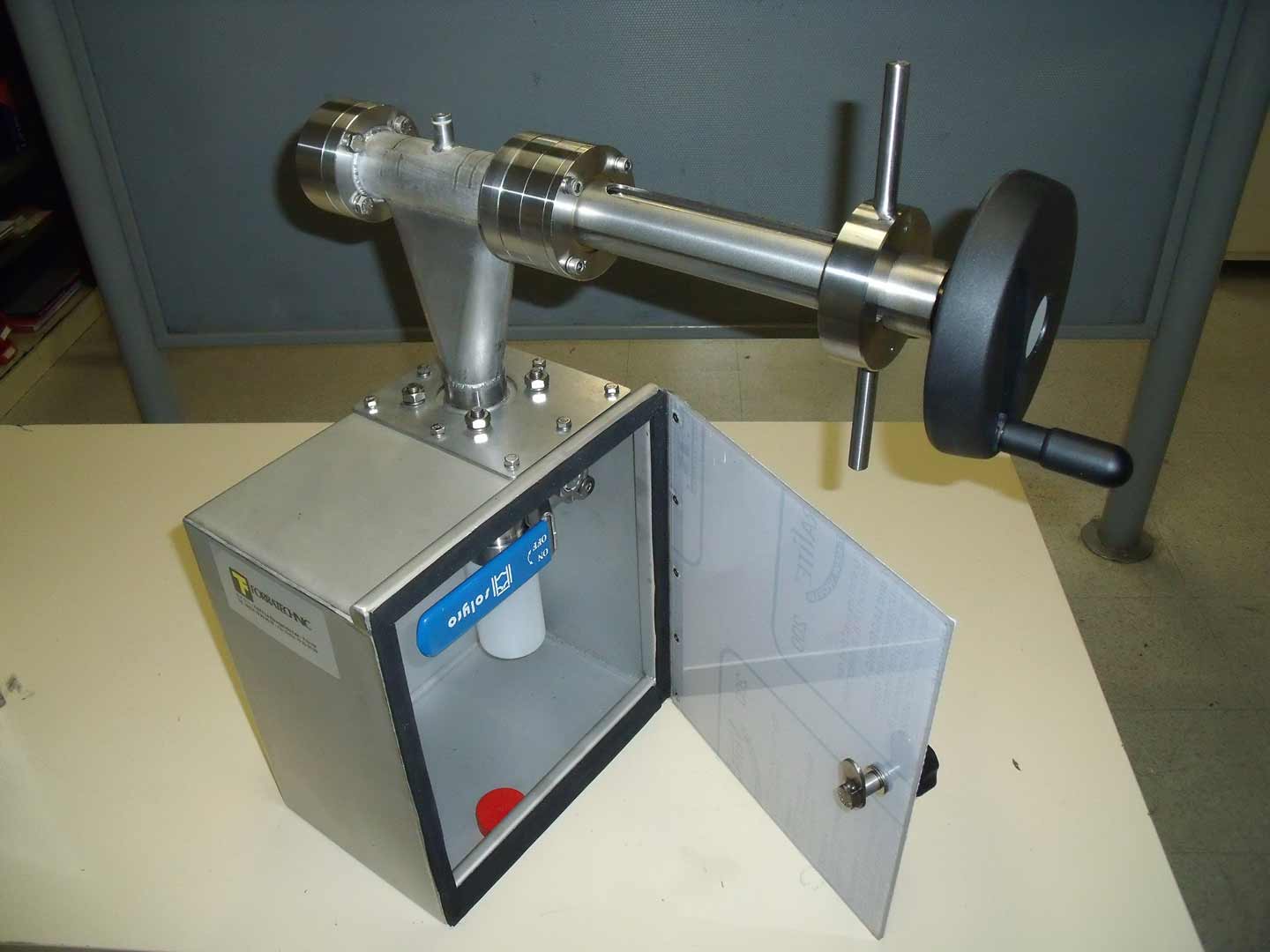

Powders, granules, agglomerates, liquids…

At rest, the sampling system has no influence on product flow. There is a seal between the sampler and the enclosure.

A spoon piston is inserted under the product flow for the time required for loading. When the scoop is full, the piston returns to its position above the sample hopper.

In this position, the spoon is turned through 180° to drain the product. The piston is repositioned flush with the flow circuit (waiting).

If necessary, a metered gas injection facilitates evacuation.

A containment chamber can be provided

The translation and rotation movements of the sampling spoon are manual.

Translation is achieved by rotating the handwheel. The orientation of the spoon (emptying/loading position) is transmitted by the positioning of the operating arms.

All parts in contact with the product are stainless steel (304 L or 316 L stainless steel, PETP, PTFE, etc.), including piston, spout and sleeve.

The manual actuator is in stainless steel and the bearings in bronze. Three models are available: Ø 33, Ø 47, Ø 75, allowing samples of up to 250 CC to be taken per maneuver.

More or less homogeneous powders, granules and agglomerates.

An Archimedean screw driven by an electric or pneumatic motor transfers the product into a chute which feeds the sample pot.

Screw dimensions (diameter and pitch) are determined by the product and flow rate required.

To install this system, the screw must be permanently present in the circuit.

Translation and rotation of the sampling spoon are performed by the geared motor unit.

The screw and chute assembly can be made of steel, stainless steel or plastic (polypropylene or similar).

Its design is such that the screw can be quickly and easily removed for cleaning.